RE: MT shift cable bushings (my impressions and a DIY)!

#1

The Delrin cable bushings I ordered Monday last week arrived today, so I installed them this evening. If anyone else has in mind to do this, the following procedure worked for me.

1. Disconnect the battery negative and wait a couple minutes. Remove the air box (top and bottom) by disconnecting the rubber air hose behind the air box, disconnecting the MAF, removing the air filter, disconnecting the lower air box rear wire harness clip, and removing the three bolts under the air filter in the air box (the TRD Quick Shifter Accessory install instructions help with this).

2. Disconnect the wire connector and support clip nearby the MAF on the same harness (use long nose pliers to press in the rear tabs to release the clip). Then disconnect the plug where the harness attaches to the fender fuse box and the support clip near it. Move the harness wiring forward and fully away from the transmission shift cables (located at the back of the transmission).

(the near MAF support clip and its two rear tabs at photo center)

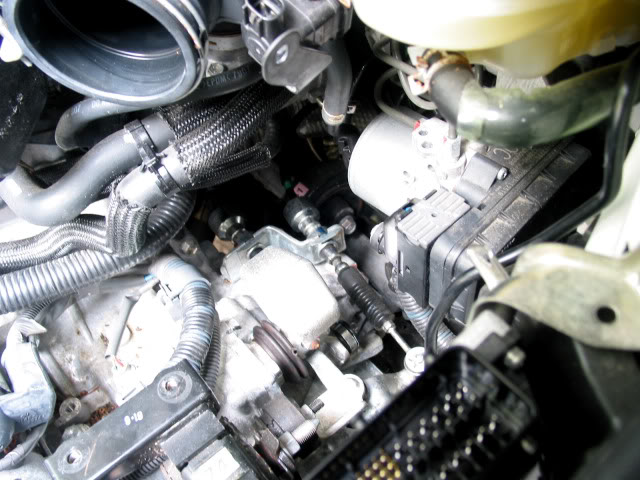

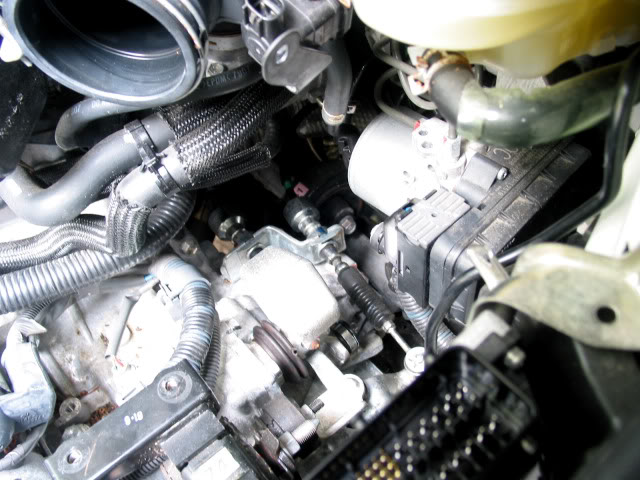

(harness out of the way and linkage exposed)

3. I then removed the two clips that secure the cable ends to the shift levers (long nose pliers) and pulled the cable ends free of the lever studs. Then remove the two U-clips that anchor the cable jackets to the support brackets. I found large offset adjustable pliers helpful in extracting the clips -- wiggle them side-to-side a little while pulling up.

(offset adjustable pliers)

4. With the U-clips out, I proceeded with one cable at a time to make sure I couldn't get confused as to which cable was which.

5. First I released the forward cable from the transmission by guiding the jacket backward through the support bracket and lifting it clear. Then I repositioned the cable forward over the transmission for easy access to the end.

6. The next step is removal of the OE bushing from the cable end, which I found to be pretty easy by grabbing the washer side with a pair of pliers and twisting and pulling at the same time.

(use pliers to remove the OE bushing)

7. The Delrin bushings are a very tight fit to the cable ends and so take your time and make sure you have the first half well in before starting on the second. When both were in, I worked around the combined halves with a pair of offset adjustable pliers to get them fully installed -- one side tends to pop out a little when the other side is pressed, so keep circling until the halves are fully in.

8. (In light of the considerable stiffness I experienced from the newly installed Delrin bushings against the shift studs, I suggest applying either a Teflon or Lithium grease to the studs before install.) The Delrin bushings require pressure plus twisting via the cable to install on the shift stud. Reinstall the OE pin (doesn't require pliers -- use your fingers), and then reposition the cable jacket in the support bracket and push in the U-clip (doesn't require pliers -- use the heel of your hand). Be sure both pin and clip are fully installed -- you don't want them popping out.

9. If the forward cable is now finished, and you're doing the rear (optional in my opinion), return to step 5 and duplicate the process with the rear cable. If all done, then reassemble everything in reverse order of dis-assembly and double check that everything is correct (no connectors left unplugged, no support clips left unclipped).

10. If all is well, reconnect the battery and try out the new bushings .

.

I'm satisfied the Delrin bushings do need to have grease applied to the shift studs before installation (my thinking is Teflon or Lithium). The bushing seller doesn't mention this, but I find the unlubricated friction unacceptable -- it completely masks the normal shift resistance of the transmission itself. On the plus side, there is an increase in solidity at entry into gears. No sign of added notchiness, just shift solidity.

1. Disconnect the battery negative and wait a couple minutes. Remove the air box (top and bottom) by disconnecting the rubber air hose behind the air box, disconnecting the MAF, removing the air filter, disconnecting the lower air box rear wire harness clip, and removing the three bolts under the air filter in the air box (the TRD Quick Shifter Accessory install instructions help with this).

2. Disconnect the wire connector and support clip nearby the MAF on the same harness (use long nose pliers to press in the rear tabs to release the clip). Then disconnect the plug where the harness attaches to the fender fuse box and the support clip near it. Move the harness wiring forward and fully away from the transmission shift cables (located at the back of the transmission).

(the near MAF support clip and its two rear tabs at photo center)

(harness out of the way and linkage exposed)

3. I then removed the two clips that secure the cable ends to the shift levers (long nose pliers) and pulled the cable ends free of the lever studs. Then remove the two U-clips that anchor the cable jackets to the support brackets. I found large offset adjustable pliers helpful in extracting the clips -- wiggle them side-to-side a little while pulling up.

(offset adjustable pliers)

4. With the U-clips out, I proceeded with one cable at a time to make sure I couldn't get confused as to which cable was which.

5. First I released the forward cable from the transmission by guiding the jacket backward through the support bracket and lifting it clear. Then I repositioned the cable forward over the transmission for easy access to the end.

6. The next step is removal of the OE bushing from the cable end, which I found to be pretty easy by grabbing the washer side with a pair of pliers and twisting and pulling at the same time.

(use pliers to remove the OE bushing)

7. The Delrin bushings are a very tight fit to the cable ends and so take your time and make sure you have the first half well in before starting on the second. When both were in, I worked around the combined halves with a pair of offset adjustable pliers to get them fully installed -- one side tends to pop out a little when the other side is pressed, so keep circling until the halves are fully in.

8. (In light of the considerable stiffness I experienced from the newly installed Delrin bushings against the shift studs, I suggest applying either a Teflon or Lithium grease to the studs before install.) The Delrin bushings require pressure plus twisting via the cable to install on the shift stud. Reinstall the OE pin (doesn't require pliers -- use your fingers), and then reposition the cable jacket in the support bracket and push in the U-clip (doesn't require pliers -- use the heel of your hand). Be sure both pin and clip are fully installed -- you don't want them popping out.

9. If the forward cable is now finished, and you're doing the rear (optional in my opinion), return to step 5 and duplicate the process with the rear cable. If all done, then reassemble everything in reverse order of dis-assembly and double check that everything is correct (no connectors left unplugged, no support clips left unclipped).

10. If all is well, reconnect the battery and try out the new bushings

.

.I'm satisfied the Delrin bushings do need to have grease applied to the shift studs before installation (my thinking is Teflon or Lithium). The bushing seller doesn't mention this, but I find the unlubricated friction unacceptable -- it completely masks the normal shift resistance of the transmission itself. On the plus side, there is an increase in solidity at entry into gears. No sign of added notchiness, just shift solidity.

Last edited by TrevorS; 07-01-2010 at 10:10 PM. Reason: clarifications and adjustments

#2

Thank you VERY much for this. My new NST cable bushings are in the mail and it's always gratifying to have others blaze the trail while I merely sit back and observe.

As you no doubt know, NonStopTuning recommends wheel bearing grease. Their bushings, however, are stainless steel, so their advice is probably not applicable to you.

Thanks again,

Marc

As you no doubt know, NonStopTuning recommends wheel bearing grease. Their bushings, however, are stainless steel, so their advice is probably not applicable to you.

Thanks again,

Marc

#3

You're welcome Marc  !

!

I just tore it down again today to make a couple changes after driving it awhile. The reason for the increase in resistance appears mainly due to the alignment of the cable ends with the cable jacket supports being slightly off. Since the cables themselves are very stiff, this results in the unyielding bushings binding somewhat against the shift studs.

The rearmost shift cable delivers the left-right motion of the shift **** and an unyielding cable bushing there doesn't appear to contribute anything to the feel of precision, just stiffness. So, I'm now trying the OE bushing on the rear, while keeping the Delrin in the front (fore-aft motion of the shift ****), except with Lithium grease to try to cut the resistance. I'll report back on how that works out. Two things I'm looking for:

1) Any loss of shift solidity with the OE bushing for left-right shift **** movement.

2) How much resistance reduction in the fore-aft **** movement with the Lithium grease applied -- I'd like to be able to feel the transmission again.

========================LATER========================

Just got back from a modest run. The Lithium grease has reduced fore-aft friction and the sense of solidity is very apparent when entering a gear, easily more so than my previous try. Also, returning to the OE bushing for the rear cable has not hurt shift precision at all, and has definitely corrected the left-right resistance issue.

IMO -- there is no advantage to replacing the rear OE cable bushing. Whereas, replacing the front OE cable bushing with unyielding material does provide greater gear entry feedback for a feeling of precision and solidity -- however, there's also an increase in shift resistance and it definitely needs to be greased. If you do grease it, might as well pull the pin on the rear and do it as well !

!

In terms of shift effectiveness, I can't consider non-yielding bushings to be at all superior to the OE, they provide more gear entry feel, but not an improved gear shift. Unless shift feel is particularly important to you, I recommend staying OE.

If I come up with anything further, I'll post it.

!

!I just tore it down again today to make a couple changes after driving it awhile. The reason for the increase in resistance appears mainly due to the alignment of the cable ends with the cable jacket supports being slightly off. Since the cables themselves are very stiff, this results in the unyielding bushings binding somewhat against the shift studs.

The rearmost shift cable delivers the left-right motion of the shift **** and an unyielding cable bushing there doesn't appear to contribute anything to the feel of precision, just stiffness. So, I'm now trying the OE bushing on the rear, while keeping the Delrin in the front (fore-aft motion of the shift ****), except with Lithium grease to try to cut the resistance. I'll report back on how that works out. Two things I'm looking for:

1) Any loss of shift solidity with the OE bushing for left-right shift **** movement.

2) How much resistance reduction in the fore-aft **** movement with the Lithium grease applied -- I'd like to be able to feel the transmission again.

========================LATER========================

Just got back from a modest run. The Lithium grease has reduced fore-aft friction and the sense of solidity is very apparent when entering a gear, easily more so than my previous try. Also, returning to the OE bushing for the rear cable has not hurt shift precision at all, and has definitely corrected the left-right resistance issue.

IMO -- there is no advantage to replacing the rear OE cable bushing. Whereas, replacing the front OE cable bushing with unyielding material does provide greater gear entry feedback for a feeling of precision and solidity -- however, there's also an increase in shift resistance and it definitely needs to be greased. If you do grease it, might as well pull the pin on the rear and do it as well

!

!In terms of shift effectiveness, I can't consider non-yielding bushings to be at all superior to the OE, they provide more gear entry feel, but not an improved gear shift. Unless shift feel is particularly important to you, I recommend staying OE.

If I come up with anything further, I'll post it.

Last edited by TrevorS; 06-23-2010 at 04:43 PM. Reason: added impressions

#4

Just to add, I installed bushings from Corsport, as I had used there products in the past on other cars and was pleased with the offerings. The metal bushings went in smooth and work great. They really tightened things up and made it feel more solid and direct. Highly recommended. I was actually the first to try out their TC bushings in the XB2 for them and now they have them up for sale.

Sorry if any of that sounds like an advertisement ...........just throwing out information.

...........just throwing out information.

Sorry if any of that sounds like an advertisement

...........just throwing out information.

...........just throwing out information.

Last edited by Puredrive; 06-23-2010 at 09:22 PM.

#6

#7

"In terms of shift effectiveness, I can't consider non-yielding bushings to be at all superior to the OE, they provide more gear entry feel, but not an improved gear shift. Unless shift feel is particularly important to you, I recommend staying OE." (TrevorS)

This is very useful. Since I've ordered them, I'll probably go ahead and install my NST shift bushing cables when they arrive - with grease. (But now I'm not going to expect much!)

By the way, I recently ordered and then had to return four Delrin shift cage bushings from Dr. Isostope. He was EXTREMEMLY responsive and helpful throughout and I highly recommend him to anyone contemplating his products. In my case, I thought that the cage bushings shown on his site - "www.doctorisotope.com/bushings" - would fit a 2nd gen. xB but, as it turned out, the "Doc" has only fabricated one set of xB cage bushings to date and has lost track of the exact dimensions needed to make more of them. For the record, the "Doc's" cage bushing are for use in tCs - NOT xBs.

If anyone has their xB shifter cage out of their car and can "mic" out the exact dimensions - i.e., the inside diameter and height of the cylindrical space where the OEM bushings normally reside - I believe that the "Doc" would be grateful.

Anyway, to get back to you Trevor, I think it's perhaps as well that I didn't obtain the cage shifter bushings that I'd though I'd wanted. For my kind of (usually sedate) driving, I probably wouldn't have realized any gain from them.

Marc

This is very useful. Since I've ordered them, I'll probably go ahead and install my NST shift bushing cables when they arrive - with grease. (But now I'm not going to expect much!)

By the way, I recently ordered and then had to return four Delrin shift cage bushings from Dr. Isostope. He was EXTREMEMLY responsive and helpful throughout and I highly recommend him to anyone contemplating his products. In my case, I thought that the cage bushings shown on his site - "www.doctorisotope.com/bushings" - would fit a 2nd gen. xB but, as it turned out, the "Doc" has only fabricated one set of xB cage bushings to date and has lost track of the exact dimensions needed to make more of them. For the record, the "Doc's" cage bushing are for use in tCs - NOT xBs.

If anyone has their xB shifter cage out of their car and can "mic" out the exact dimensions - i.e., the inside diameter and height of the cylindrical space where the OEM bushings normally reside - I believe that the "Doc" would be grateful.

Anyway, to get back to you Trevor, I think it's perhaps as well that I didn't obtain the cage shifter bushings that I'd though I'd wanted. For my kind of (usually sedate) driving, I probably wouldn't have realized any gain from them.

Marc

#9

#10

"In terms of shift effectiveness, I can't consider non-yielding bushings to be at all superior to the OE, they provide more gear entry feel, but not an improved gear shift. Unless shift feel is particularly important to you, I recommend staying OE." (TrevorS)

This is very useful. Since I've ordered them, I'll probably go ahead and install my NST shift bushing cables when they arrive - with grease. (But now I'm not going to expect much!)

This is very useful. Since I've ordered them, I'll probably go ahead and install my NST shift bushing cables when they arrive - with grease. (But now I'm not going to expect much!)

Installing a nonyielding bushing in the rear cable is likely to increase right-left shift **** resistance, but otherwise contribute nothing.

..., I think it's perhaps as well that I didn't obtain the cage shifter bushings that I'd though I'd wanted. For my kind of (usually sedate) driving, I probably wouldn't have realized any gain from them.

Marc

Marc

!

!

#11

So not the highjack the thread, but in regards to improving shifting action/feel has anyone replaced the front engine mount yet? I am very close to ordering one from NurSpec - 70A durometer. I know in other cars I have had over the years replacing the engine mount with a stiffer aftermarket part resulted in a much more solid and controlled shifting experience -getting rid of that "rubber band" or bouncing feeling that can happen with soft factory mounts. Of course, with a stiffer mount usually comes vibration. I know in my last car, a VW GTI, the engine mount was fine as far as vibrations, but doing the transmission mount caused the car to shudder horribly. Just seeing if anyone has tried them out for the xB2?

#12

Puredrive:

Have you read these threads from early last year? There are a couple more I can't find as well ...

https://www.scionlife.com/forums/sho...=stiffer+mount

https://www.scionlife.com/forums/sho...d.php?t=153956

Marc

Have you read these threads from early last year? There are a couple more I can't find as well ...

https://www.scionlife.com/forums/sho...=stiffer+mount

https://www.scionlife.com/forums/sho...d.php?t=153956

Marc

#14

), but I've followed the discussion on those mounts (in fact, I provided the original OE mount photos when NurSpec was evaluating the xB2 application).

), but I've followed the discussion on those mounts (in fact, I provided the original OE mount photos when NurSpec was evaluating the xB2 application).I've no personal experience, and don't expect to be getting any. They seem like an appropriate option for a race oriented vehicle, but from what I've read from other-usage owner's, they seem to transmit more vibration than most are comfortable with. Still, that's entirely a question of personal tolerances

!

!

#18

I've seen an MT fluid change credited for improved shifting, and I've seen it credited with accomplishing nothing at all (at least with the TRD Short Shifter). What's the truth on this? (I run Pennzoil Syncromesh in my Eclipse MT and it definitely makes a difference, what makes a definite difference for the xB2 MT?)

#19

TrevorS:

I replaced my xB's M/T fluid with Amsoil 75W-90 (Type: "Manual Transaxle" - NOT "Severe") at 1,600 miles. I had previously installed a TRD Quick Shiifter, and I just swapped the OEM shift bushings for rigid ones this last weekend.

Conclusion:

You were correct in saying the more rigid bushings contribute to 'feel' - i.e., increased mechanical feedback from the transmission - but not at all to the smoothness with which gear changes can be felt and/or accomplished. In fact, my transmission feels more "notchy" than before the bushing install, especially when changing into reverse, 1st or 2nd (in that order).

Having said that, I'm VERY happy with the NST bushings. In combination with my TRD Quick Shifter, I can feel exctly what's happening when I up-shift, down-shift, double-clutch, et cetera. (I am the sort of gear-head who insists on being close to the action, not isolated from it!)

In answer to your last question, the best thing I've done for my car to date is to change out the M/T fluid. Doing so was immediately (and pleasingly) evident, and I recommend it to anyone. My total cost was $36.00 for the oil (paid locally); and my local 10-minute oil change shop did the actual drain-and-fill for another $25.00.

http://www.amsoil.com/storefront/mtg.aspx (You need 2.6 qts. total)

Marc

I replaced my xB's M/T fluid with Amsoil 75W-90 (Type: "Manual Transaxle" - NOT "Severe") at 1,600 miles. I had previously installed a TRD Quick Shiifter, and I just swapped the OEM shift bushings for rigid ones this last weekend.

Conclusion:

You were correct in saying the more rigid bushings contribute to 'feel' - i.e., increased mechanical feedback from the transmission - but not at all to the smoothness with which gear changes can be felt and/or accomplished. In fact, my transmission feels more "notchy" than before the bushing install, especially when changing into reverse, 1st or 2nd (in that order).

Having said that, I'm VERY happy with the NST bushings. In combination with my TRD Quick Shifter, I can feel exctly what's happening when I up-shift, down-shift, double-clutch, et cetera. (I am the sort of gear-head who insists on being close to the action, not isolated from it!)

In answer to your last question, the best thing I've done for my car to date is to change out the M/T fluid. Doing so was immediately (and pleasingly) evident, and I recommend it to anyone. My total cost was $36.00 for the oil (paid locally); and my local 10-minute oil change shop did the actual drain-and-fill for another $25.00.

http://www.amsoil.com/storefront/mtg.aspx (You need 2.6 qts. total)

Marc

#20

! It's not clear what exactly was improved by your MT fluid change, could you elaborate a little?

! It's not clear what exactly was improved by your MT fluid change, could you elaborate a little?