Burning Oil After Turbo Install?

#1

Senior Member

SL Member

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Location: Jacksonville, FL

Posts: 1,267

So during my turbo install, my car blew smoke out the exhaust. I assumed it was just because of the new turbo being installed and it was burning out all the oil that got on the downpipe during the install. I assumed it would stop once all of the oiled was burned off the pipe, but after a few days and a 150 mile trip it's still blowing smoke out the exhaust. It's blue smoke so I assume it's burning oil, but I have no idea where the heck from! I does not appear to be affecting performance, but it's definitely not a good thing for it to be burning oil like this.

http://www.youtube.com/watch?v=4Bx7D...ature=youtu.be

Anyone have any ideas what's going on?? I plan on taking it to a performance shop this weekend and see if they know anything, but I hate giving in and letting someone else work on my car :/

http://www.youtube.com/watch?v=4Bx7D...ature=youtu.be

Anyone have any ideas what's going on?? I plan on taking it to a performance shop this weekend and see if they know anything, but I hate giving in and letting someone else work on my car :/

#2

Seals in the turbo? Oil line from turbo to pan bent or make a bunch of twists that would prevent flow? Those are two that I think ppl have said. When is smoke visible. All the time? Idle? Accelerating? Decel?

#3

Senior Member

SL Member

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Location: Jacksonville, FL

Posts: 1,267

I'm not sure how to check the seals in the turbo, it came assembled from Descendant; and i'm not sure about the twists in the oil return line, i'll have to double check it. As shown in the video, little smoke is visible at idle, and a ton of smoke is visible as the RPM's go higher.

#8

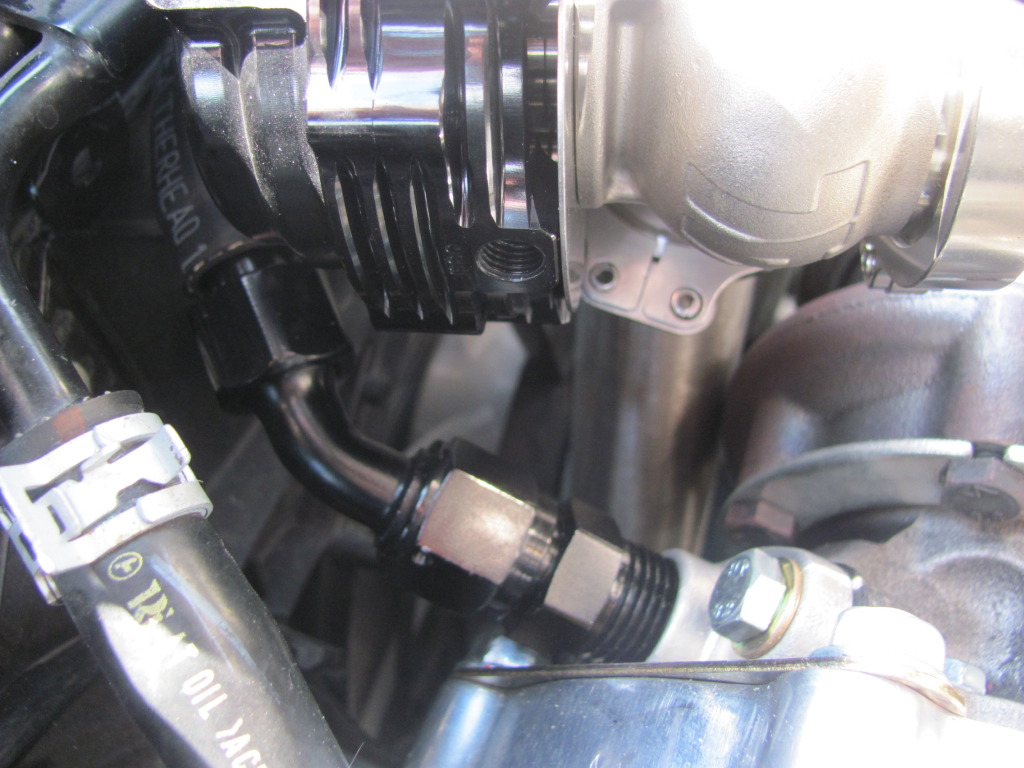

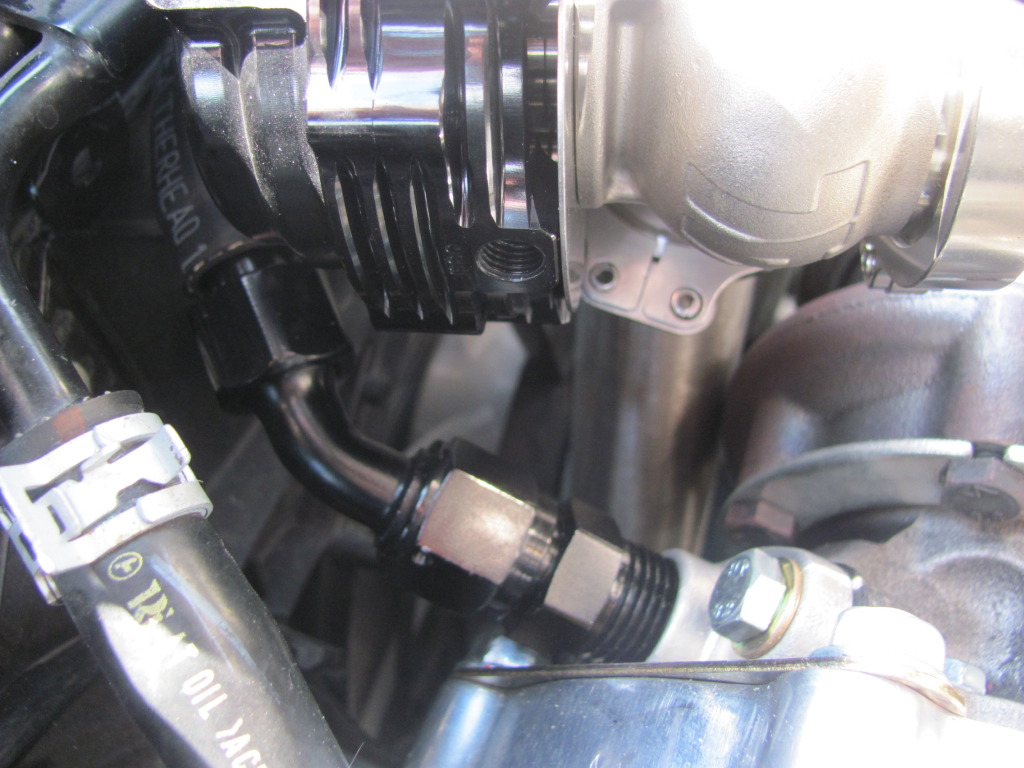

1. send us a photo of the orientation of the body of the turbo (between the turbine and the compressor) with a plumb line so we can see that the oil out is pointing directly down.

2. send us a photo of your oil drain line (from the turbo body to the oil pan). If it is not constantly decending (no ups), then that is your problem.

3. send us a photo of where in the oil pan that same drain line goes into the pan. If it is below the oil level in the pan, that is your problem.

4. is the drain line at least an AN-8 (1/2") in size all the way - INCLUNING THE FITTINGS. If it is not, that is your problem.

5. If all of these check good, then you have a bad seal on the compressor side of your turbo...you will have to send it back.

2. send us a photo of your oil drain line (from the turbo body to the oil pan). If it is not constantly decending (no ups), then that is your problem.

3. send us a photo of where in the oil pan that same drain line goes into the pan. If it is below the oil level in the pan, that is your problem.

4. is the drain line at least an AN-8 (1/2") in size all the way - INCLUNING THE FITTINGS. If it is not, that is your problem.

5. If all of these check good, then you have a bad seal on the compressor side of your turbo...you will have to send it back.

#9

Senior Member

SL Member

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Location: Jacksonville, FL

Posts: 1,267

1. send us a photo of the orientation of the body of the turbo (between the turbine and the compressor) with a plumb line so we can see that the oil out is pointing directly down.

2. send us a photo of your oil drain line (from the turbo body to the oil pan). If it is not constantly decending (no ups), then that is your problem.

3. send us a photo of where in the oil pan that same drain line goes into the pan. If it is below the oil level in the pan, that is your problem.

4. is the drain line at least an AN-8 (1/2") in size all the way - INCLUNING THE FITTINGS. If it is not, that is your problem.

5. If all of these check good, then you have a bad seal on the compressor side of your turbo...you will have to send it back.

2. send us a photo of your oil drain line (from the turbo body to the oil pan). If it is not constantly decending (no ups), then that is your problem.

3. send us a photo of where in the oil pan that same drain line goes into the pan. If it is below the oil level in the pan, that is your problem.

4. is the drain line at least an AN-8 (1/2") in size all the way - INCLUNING THE FITTINGS. If it is not, that is your problem.

5. If all of these check good, then you have a bad seal on the compressor side of your turbo...you will have to send it back.

First of all, Thank you so much for posting this!!

I believe the first or second points you posted are the problem. I will definitely post pictures on here just to be sure before I adjust anything.

#10

Senior Member

SL Member

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Location: Jacksonville, FL

Posts: 1,267

I can't believe I did this..

Correct me if I am wrong, but a Turbo drains oil using nothing but gravity right? Then the Oil drain should be on the bottom of the turbo, and the oil in should be on the top. Otherwise, the oil will not be able to train out of the turbo, and will drip into the down pipe, which I believe is what is causing all of the smoke.

So there are 2 ports on the turbo, can either one be used for an inlet and outlet? I believe I may have them switched. The oil drain has a sort of adapter that goes on it, and then the oil drain line connects to it. Can the oil drain and the oil in be switched? Or are the specific? Like oil can only go in one way and out one way.

Here are the pics.

Can anyone confirm if I am right or wrong? I believe that if I switch the oil in and drain then it will be ok. Unless they can't be switched?

The oil drain is pointing slightly up, slightly sideways. But from the position it is in. It cannot be pointing down because it will hit the fans.

Correct me if I am wrong, but a Turbo drains oil using nothing but gravity right? Then the Oil drain should be on the bottom of the turbo, and the oil in should be on the top. Otherwise, the oil will not be able to train out of the turbo, and will drip into the down pipe, which I believe is what is causing all of the smoke.

So there are 2 ports on the turbo, can either one be used for an inlet and outlet? I believe I may have them switched. The oil drain has a sort of adapter that goes on it, and then the oil drain line connects to it. Can the oil drain and the oil in be switched? Or are the specific? Like oil can only go in one way and out one way.

Here are the pics.

Can anyone confirm if I am right or wrong? I believe that if I switch the oil in and drain then it will be ok. Unless they can't be switched?

The oil drain is pointing slightly up, slightly sideways. But from the position it is in. It cannot be pointing down because it will hit the fans.

#11

Back when I worked for Garrett AiResearch in Torrance, the drain side was a smooth hole with two treaded holes on either side for an adapter plate. The oil supply side was one threaded hole for a positive connection/supply. From your photos, it looks like your oil drain is facing upwards! That is your problem. Oil is just gravity drained from the turbo, just like the rest of your engine. It makes a big difference for supply and drain…do not reverse them.

#12

Senior Member

SL Member

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Location: Jacksonville, FL

Posts: 1,267

How do I get the oil drain on the bottom then? If I can't switch the lines, then do I have to rotate the turbo? But I can't rotate it because the pipe from the turbo to the intercooler can't really be moved, that's the only spot it fits!

#13

Senior Member

SL Member

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Location: Jacksonville, FL

Posts: 1,267

After looking at tons of pictures of Turbo's online, I realized the problem. The Oil feed is supposed to be on the top and the Oil drain is supposed to be on the bottom. That should be common sense! Gosh, dumb move on my part. Now it's just a matter of how am I going to get it in a position where the oil feed can be on the top and the oil return can be on the bottom!

#14

Really? Are you serious? You can’t figure out that that the center bearing housing of a turbocharger rotates freely after just loosening a few bolts? Then you shouldn’t even be touching the engine of a car! Who turboed your car? Take it back to them and tell them to fix it.

#15

^ some of us grew up with 80's turbo cars, that didn't have rotatable in/ex sides of the turbo.

He is 18. He realized something was wrong, and asked a knowledgeable group a question. I hardly think that disqualifies him to ever "be allowed to touch the engine a car".

Hope you get it up and running soon.

He is 18. He realized something was wrong, and asked a knowledgeable group a question. I hardly think that disqualifies him to ever "be allowed to touch the engine a car".

Hope you get it up and running soon.

#16

Senior Member

SL Member

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Location: Jacksonville, FL

Posts: 1,267

I understand that it rotates once you loosen a few of the bolts, but I didn't realize the actual center rotates? After looking at pictures more and looking at the turbo, I can now see how if I loosen the bolts on both sides of the center how I could rotate. I only rotated the Chrome part from the metal part as a whole during the install.

As Roller Toaster said, I'm 18. I've taught myself everything I know about cars. I've installed everything on my car by myself, including this turbo without any instructions. I don't think that qualifies me as a professional, but I feel that I'm hardly disqualified to ever "be allowed to touch the engine of a car".

I noticed something was wrong, and after a little research identified the source of the problem and intend to fix it.

How else am I going to learn about working on cars? Experience is the best way. I'm currently majoring in Mechanical Engineering at UCF, but hands on experience is the only way to gain knowledge.

I posted on here and asked a question, because I acknowledge that a large amount of people on here have more automotive knowledge than I do. Once again, I'm 18 and learning. But I feel for 18, I'm pretty mechanically inclined.

As Roller Toaster said, I'm 18. I've taught myself everything I know about cars. I've installed everything on my car by myself, including this turbo without any instructions. I don't think that qualifies me as a professional, but I feel that I'm hardly disqualified to ever "be allowed to touch the engine of a car".

I noticed something was wrong, and after a little research identified the source of the problem and intend to fix it.

How else am I going to learn about working on cars? Experience is the best way. I'm currently majoring in Mechanical Engineering at UCF, but hands on experience is the only way to gain knowledge.

I posted on here and asked a question, because I acknowledge that a large amount of people on here have more automotive knowledge than I do. Once again, I'm 18 and learning. But I feel for 18, I'm pretty mechanically inclined.

Last edited by ProjectTC2; 09-24-2012 at 03:41 AM.

#17

I understand that it rotates once you loosen a few of the bolts, but I didn't realize the actual center rotates? After looking at pictures more and looking at the turbo, I can now see how if I loosen the bolts on both sides of the center how I could rotate. I only rotated the Chrome part from the metal part as a whole during the install.

As Roller Toaster said, I'm 18. I've taught myself everything I know about cars. I've installed everything on my car by myself, including this turbo without any instructions. I don't think that qualifies me as a professional, but I feel that I'm hardly disqualified to ever "be allowed to touch the engine of a car".

I noticed something was wrong, and after a little research identified the source of the problem and intend to fix it.

How else am I going to learn about working on cars? Experience is the best way. I'm currently majoring in Mechanical Engineering at UCF, but hands on experience is the only way to gain knowledge.

I posted on here and asked a question, because I acknowledge that a large amount of people on here have more automotive knowledge than I do. Once again, I'm 18 and learning. But I feel for 18, I'm pretty mechanically inclined.

As Roller Toaster said, I'm 18. I've taught myself everything I know about cars. I've installed everything on my car by myself, including this turbo without any instructions. I don't think that qualifies me as a professional, but I feel that I'm hardly disqualified to ever "be allowed to touch the engine of a car".

I noticed something was wrong, and after a little research identified the source of the problem and intend to fix it.

How else am I going to learn about working on cars? Experience is the best way. I'm currently majoring in Mechanical Engineering at UCF, but hands on experience is the only way to gain knowledge.

I posted on here and asked a question, because I acknowledge that a large amount of people on here have more automotive knowledge than I do. Once again, I'm 18 and learning. But I feel for 18, I'm pretty mechanically inclined.

You might have a much bigger problem now…depending on how much oil was left in the turbo housing and how long you’ve run your engine - the turbine will have cooked the oil and could have coked up the inside of the bearing housing. This is the brown looking shellac that coats the inside of a motor. It is a much bigger problem in the turbo…unless you run fully synthetic oil in your engine…then you should be OK. If not, this will freeze the full floating bearings and/or restrict your oil galleys. You will then need to tear it all down to clean it out. Word to the wise…special tools are needed to get the circlips out of the housing.

Last edited by 2tCornot2tC; 09-24-2012 at 12:55 PM.

#18

Senior Member

SL Member

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Location: Jacksonville, FL

Posts: 1,267

I didn't piece the turbo together, I purchased a Descendant Bolt on Turbo Kit and am just installing that. I'm fully aware that I would be WAY over my head if I tried to build one!! I run full synthetic oil in my car, would it be ok to drive home to fix it, or do I need to do it here? My home is roughly 150 miles, and I would drive under 3000 RPM's the whole way to be sure not to harm anything. I have no tools here to fix it

#19

Fully synthetic motor oil like Mobile-1 is your only savior here.

First check your oil quantity! I’m assuming that you drove 150 miles to get to where you are at now… If you didn’t burn a quart of oil getting there, I would drive it back. You will have to replace your spark plugs when you get back.

There were no instructions with the Decendant turbo kit? The orientation of the bearing housing of a turbo is the one most important bit of installation information that can be provided. I’d be very surprised if it was not in red and bold in the installation instructions.

First check your oil quantity! I’m assuming that you drove 150 miles to get to where you are at now… If you didn’t burn a quart of oil getting there, I would drive it back. You will have to replace your spark plugs when you get back.

There were no instructions with the Decendant turbo kit? The orientation of the bearing housing of a turbo is the one most important bit of installation information that can be provided. I’d be very surprised if it was not in red and bold in the installation instructions.

#20

Senior Member

SL Member

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Location: Jacksonville, FL

Posts: 1,267

Lucky for me I use full synthetic Mobile 1!

I've been continuously checking my oil quantity since I installed my Turbo, and it does not appear to have dropped at all, so that's a plus. I will definitely look into replacing my spark plugs when I get back. What is the reason they should be replaced?

My Descendant Bolt on Turbo kit didn't come with any instructions at all. My only knowledge on how it should go was from a google image search! I was practically winging it. If this is the only thing that I messed up on, I'll be fine with it!

I've been continuously checking my oil quantity since I installed my Turbo, and it does not appear to have dropped at all, so that's a plus. I will definitely look into replacing my spark plugs when I get back. What is the reason they should be replaced?

My Descendant Bolt on Turbo kit didn't come with any instructions at all. My only knowledge on how it should go was from a google image search! I was practically winging it. If this is the only thing that I messed up on, I'll be fine with it!