TB Performance Products Chassis Braces

#1

Hello Scionlife! We are back! Some of you may not be aware of who we are or what we do so quick back story! We are TB Performance Products and we specialize in hand building the best chassis braces possible. We started building products for the speed3 and quickly came to the Scion Community. Since then we have made our emphasis the scion world. We actively participate in local scion events and I think its safe to say that you guys have become one of our favorite communities to work with. The amount of passion and energy you all exude for your cars truly is unparalleled.

Off our soapbox and down to some business! We have been changing a ton of things lately and wanted to keep you all posted on whats going on with TB! You can check us out at Tbperformanceproducts.com

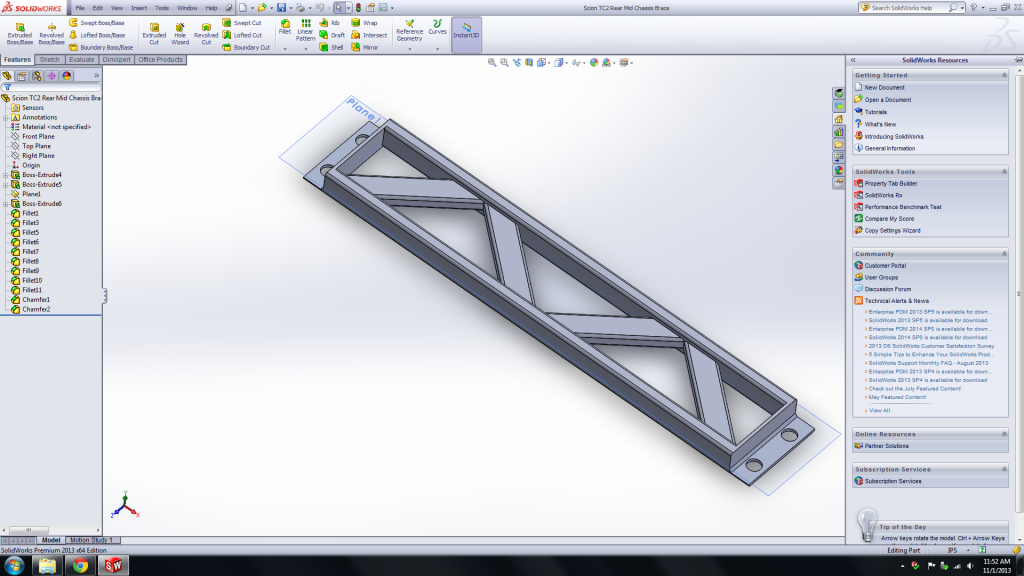

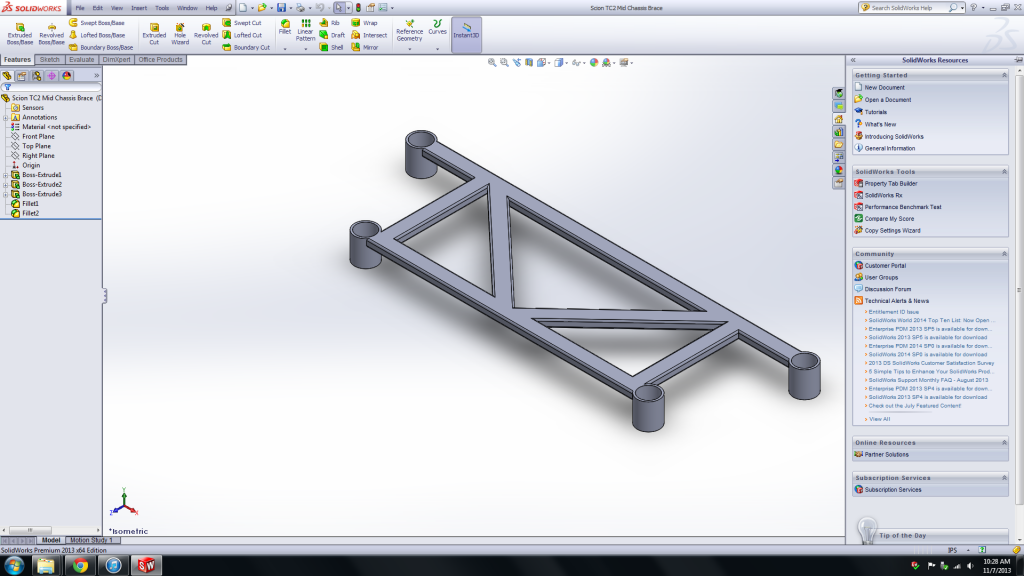

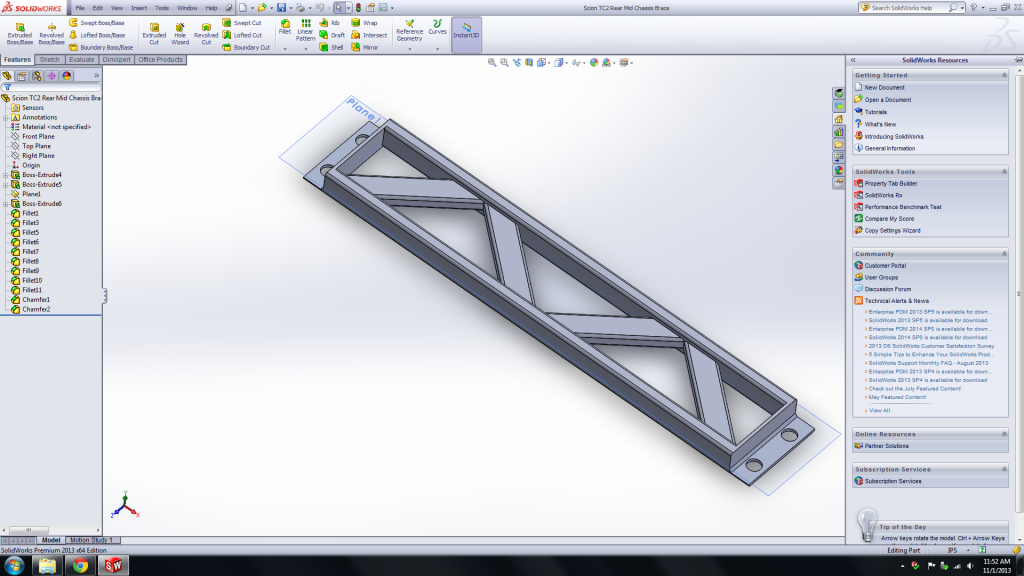

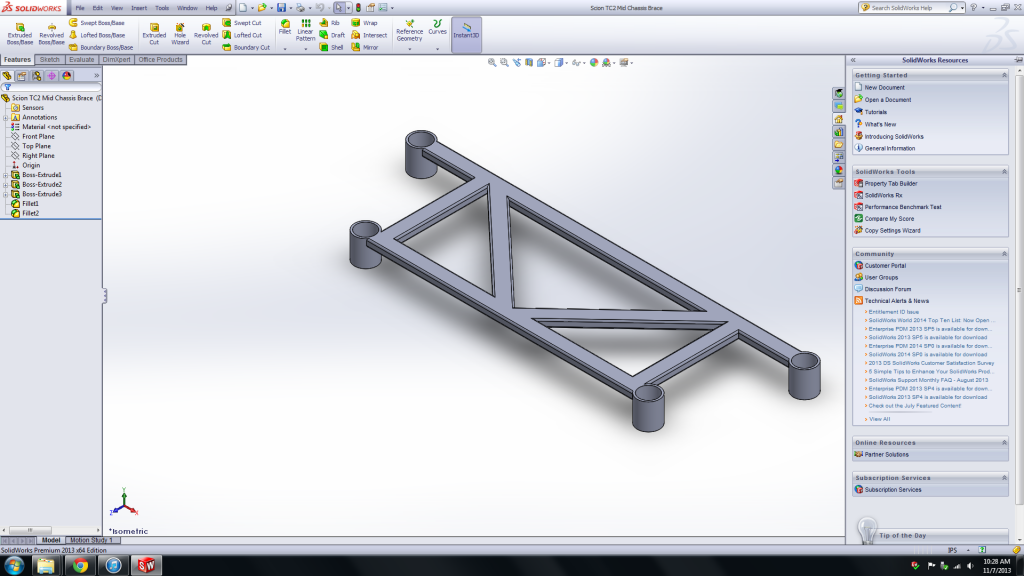

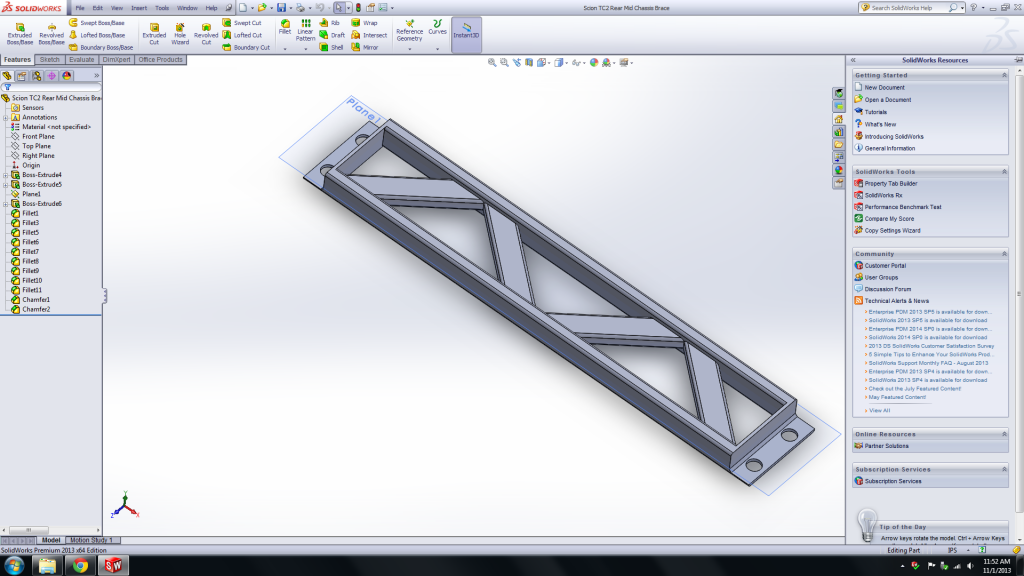

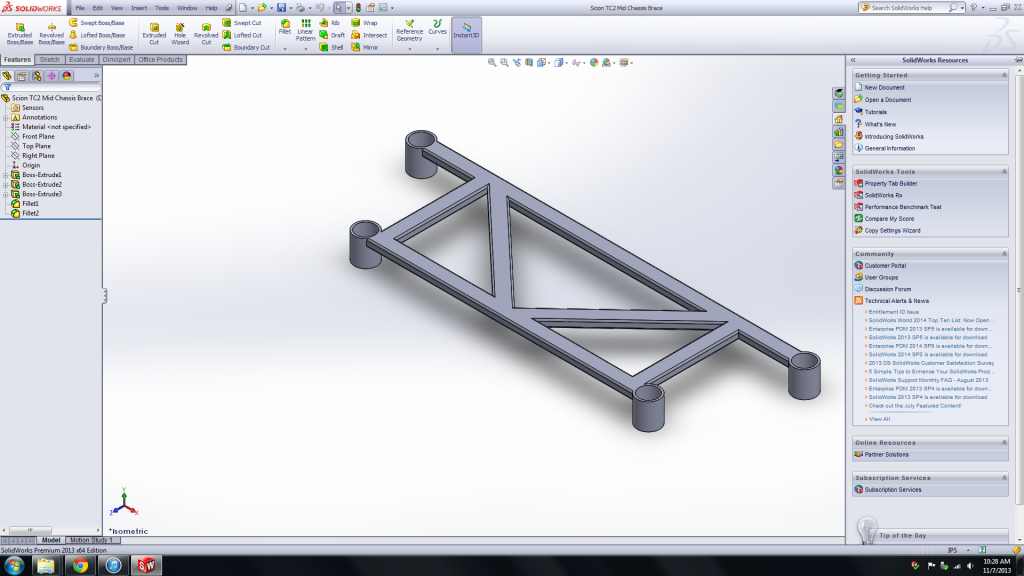

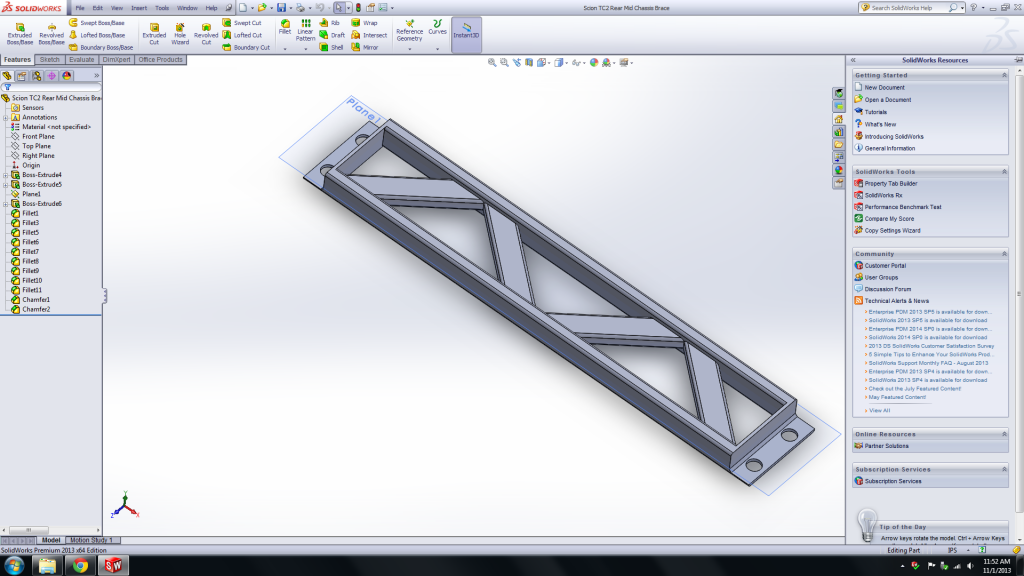

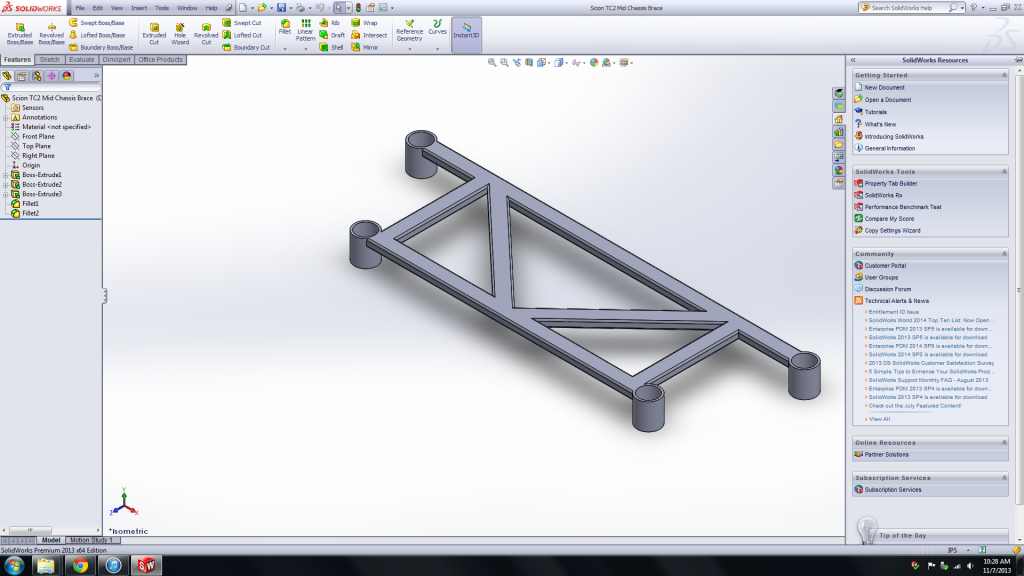

1.) Most importantly we have started using Solidworks 3D modeling and testing software to design revise and test our products to ensure that you guys always get the best product that we can conceive. We encourage you all to look up the Solidworks software and see just how much we can do with this and think about the impact itll make on your products!

2.) We recently changed material from a 1x1/2 inch rectangular tubing(still used on braces that benefit from it) to a 5/8" square tubing. It has a wall thickness of .065" and is stronger than our rectangular stock(when the rectangular stock was laid flat...on edge it is still potent and that is why we still use it on some braces) however it weighs in at significantly less. most of our braces weigh in at under 3lbs! The choice of steel is a simple one, More rigidity for braces and the weight is honestly not a problem! I have personally had to use a grinder and cut off wheel to remove Gt spec and Tanabe braes. They use a thin aluminium that caves in when hit by a rock, speed bump small child...well you get the point. steel has a much better ability to resist damage while riding under the car!

3.) Our coating is now a high strength Polymer coating similar to truck bed coating(formula is slightly different to give us a little better abrasion resistance) Its a thick black textured feeling that not only works efficiently but also gives the look and feel of a brace like no one else produces.

Our products list for both the TC2 and XB2(same chassis) include the following braces.

Rear Mid Chassis Brace-

Traction Bar-

Trunk Brace-

Adjustable C Pillar Brace-

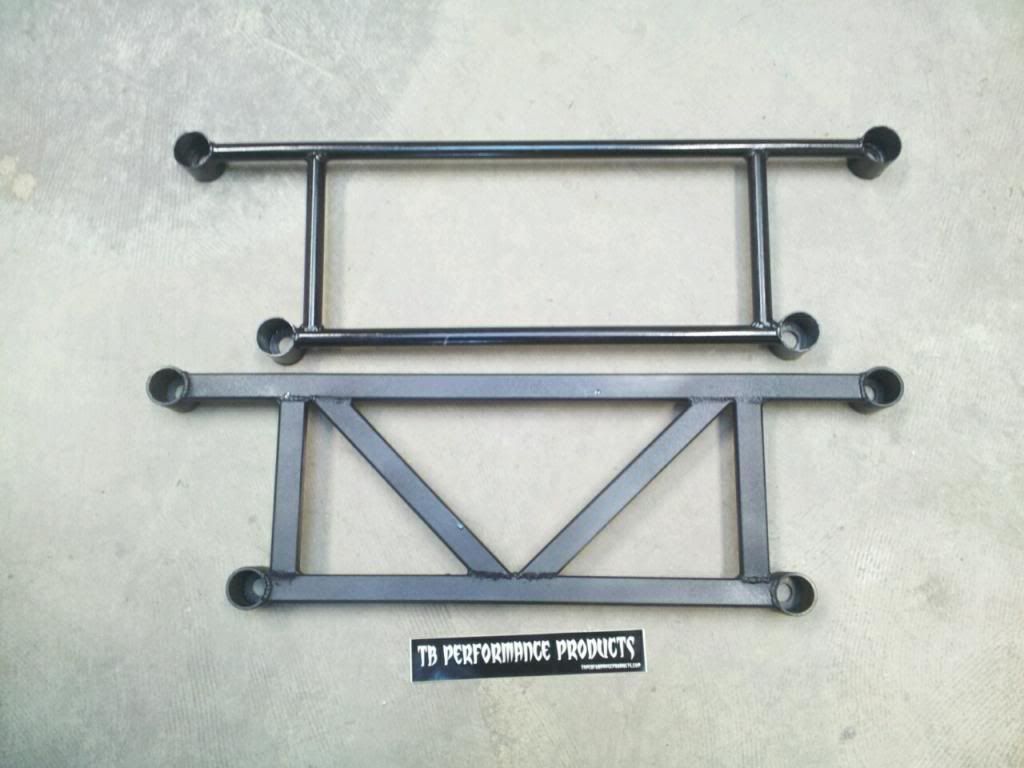

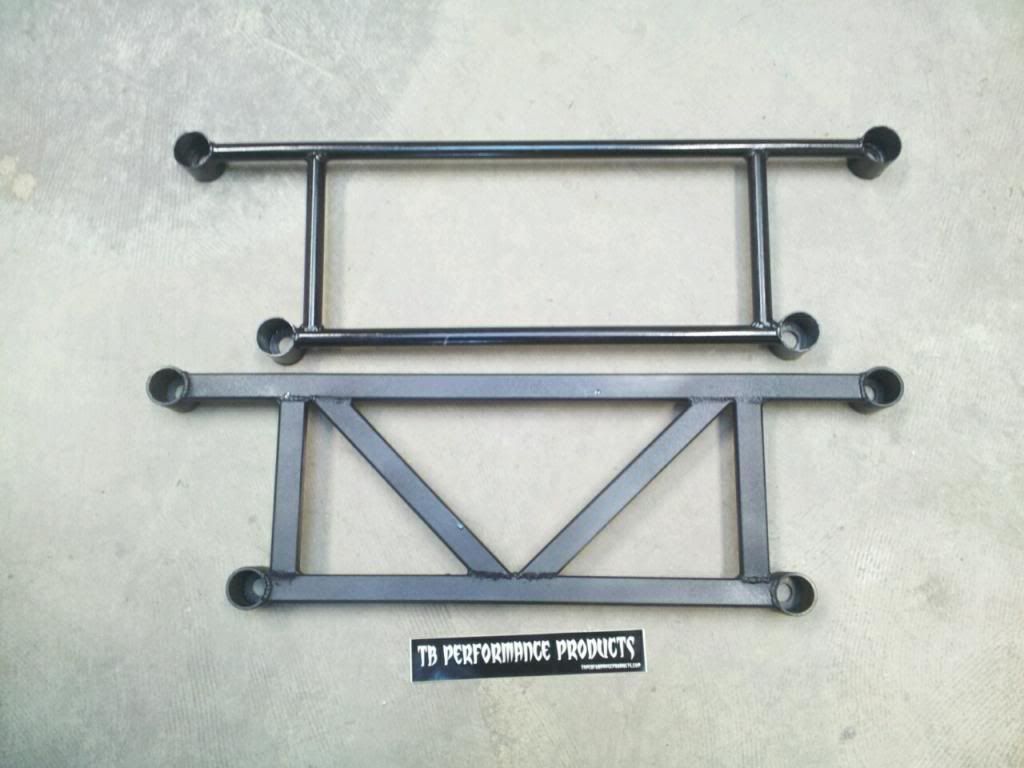

Mid Chassis Brace v2.0-(as compared to the V1.0 shown on top)

Everything is up on our site at tbperformanceproducts.com or shoot us an email at tbperformanceproducts@gmail.com and well get back to you within a few hours! Also dont forget to add us on facebook!

Off our soapbox and down to some business! We have been changing a ton of things lately and wanted to keep you all posted on whats going on with TB! You can check us out at Tbperformanceproducts.com

1.) Most importantly we have started using Solidworks 3D modeling and testing software to design revise and test our products to ensure that you guys always get the best product that we can conceive. We encourage you all to look up the Solidworks software and see just how much we can do with this and think about the impact itll make on your products!

2.) We recently changed material from a 1x1/2 inch rectangular tubing(still used on braces that benefit from it) to a 5/8" square tubing. It has a wall thickness of .065" and is stronger than our rectangular stock(when the rectangular stock was laid flat...on edge it is still potent and that is why we still use it on some braces) however it weighs in at significantly less. most of our braces weigh in at under 3lbs! The choice of steel is a simple one, More rigidity for braces and the weight is honestly not a problem! I have personally had to use a grinder and cut off wheel to remove Gt spec and Tanabe braes. They use a thin aluminium that caves in when hit by a rock, speed bump small child...well you get the point. steel has a much better ability to resist damage while riding under the car!

3.) Our coating is now a high strength Polymer coating similar to truck bed coating(formula is slightly different to give us a little better abrasion resistance) Its a thick black textured feeling that not only works efficiently but also gives the look and feel of a brace like no one else produces.

Our products list for both the TC2 and XB2(same chassis) include the following braces.

Rear Mid Chassis Brace-

Traction Bar-

Trunk Brace-

Adjustable C Pillar Brace-

Mid Chassis Brace v2.0-(as compared to the V1.0 shown on top)

Everything is up on our site at tbperformanceproducts.com or shoot us an email at tbperformanceproducts@gmail.com and well get back to you within a few hours! Also dont forget to add us on facebook!

Last edited by TB_Performance_Products; 11-08-2013 at 05:32 AM.

#2

Hello Scionlife! We are back! Some of you may not be aware of who we are or what we do so quick back story! We are TB Performance Products and we specialize in hand building the best chassis braces possible. We started building products for the speed3 and quickly came to the Scion Community. Since then we have made our emphasis the scion world. We actively participate in local scion events and I think its safe to say that you guys have become one of our favorite communities to work with. The amount of passion and energy you all exude for your cars truly is unparalleled.

Off our soapbox and down to some business! We have been changing a ton of things lately and wanted to keep you all posted on whats going on with TB! You can check us out at Tbperformanceproducts.com

1.) Most importantly we have started using Solidworks 3D modeling and testing software to design revise and test our products to ensure that you guys always get the best product that we can conceive. We encourage you all to look up the Solidworks software and see just how much we can do with this and think about the impact itll make on your products!

2.) We recently changed material from a 1x1/2 inch rectangular tubing(still used on braces that benefit from it) to a 5/8" square tubing. It has a wall thickness of .065" and is stronger than our rectangular stock(when the rectangular stock was laid flat...on edge it is still potent and that is why we still use it on some braces) however it weighs in at significantly less. most of our braces weigh in at under 3lbs! The choice of steel is a simple one, More rigidity for braces and the weight is honestly not a problem! I have personally had to use a grinder and cut off wheel to remove Gt spec and Tanabe braes. They use a thin aluminium that caves in when hit by a rock, speed bump small child...well you get the point. steel has a much better ability to resist damage while riding under the car!

3.) Our coating is now a high strength Polymer coating similar to truck bed coating(formula is slightly different to give us a little better abrasion resistance) Its a thick black textured feeling that not only works efficiently but also gives the look and feel of a brace like no one else produces.

Our products list for both the TC2 and XB2(same chassis) include the following braces.

Rear Mid Chassis Brace-

Traction Bar-

Trunk Brace-

Adjustable C Pillar Brace-

Mid Chassis Brace v2.0-(as compared to the V1.0 shown on top)

Everything is up on our site at tbperformanceproducts.com or shoot us an email at tbperformanceproducts@gmail.com and well get back to you within a few hours! Also dont forget to add us on facebook!

Off our soapbox and down to some business! We have been changing a ton of things lately and wanted to keep you all posted on whats going on with TB! You can check us out at Tbperformanceproducts.com

1.) Most importantly we have started using Solidworks 3D modeling and testing software to design revise and test our products to ensure that you guys always get the best product that we can conceive. We encourage you all to look up the Solidworks software and see just how much we can do with this and think about the impact itll make on your products!

2.) We recently changed material from a 1x1/2 inch rectangular tubing(still used on braces that benefit from it) to a 5/8" square tubing. It has a wall thickness of .065" and is stronger than our rectangular stock(when the rectangular stock was laid flat...on edge it is still potent and that is why we still use it on some braces) however it weighs in at significantly less. most of our braces weigh in at under 3lbs! The choice of steel is a simple one, More rigidity for braces and the weight is honestly not a problem! I have personally had to use a grinder and cut off wheel to remove Gt spec and Tanabe braes. They use a thin aluminium that caves in when hit by a rock, speed bump small child...well you get the point. steel has a much better ability to resist damage while riding under the car!

3.) Our coating is now a high strength Polymer coating similar to truck bed coating(formula is slightly different to give us a little better abrasion resistance) Its a thick black textured feeling that not only works efficiently but also gives the look and feel of a brace like no one else produces.

Our products list for both the TC2 and XB2(same chassis) include the following braces.

Rear Mid Chassis Brace-

Traction Bar-

Trunk Brace-

Adjustable C Pillar Brace-

Mid Chassis Brace v2.0-(as compared to the V1.0 shown on top)

Everything is up on our site at tbperformanceproducts.com or shoot us an email at tbperformanceproducts@gmail.com and well get back to you within a few hours! Also dont forget to add us on facebook!

I can image if u drop the car race like it would definitely increase the chance of scraping more. I think if u guys make the front under brace similar to the mid it will give it more clearance. Overall the braces kick ___. Oh ya I have to recoat my bar with vht antirust because the one that came started peeling off. The brace that came wasnt much coated with paint.

#3

Oh yah when I say front under brace I ment the traction bar. I hit a couple low dip in city to city drive twice. That bar scrape the ground twice. If u guys can make that bar flat like the mid brace. I can have it on all seasons. Also have the car race drop and not worry. When I say dip its a small one not a huge pot hole.

#4

We cannot make the bar sit any higher to the vehicle because it will not clear aftermaket and stock S pipes. When we build braces we design them to sit as closr to the vehicle as possible so anytime there is a taller cup its to clear something on the car or for safety. A common thing that happens with other companies is that they will make the braces sit CLOSE to the chassis of the car but the driver will experience a ton of rattling and vibrations from it rubbing up against motor mounts, crossmembers, exhaust systems etc...It really becomes a choice of scraping occasionally or having constant rattles. One of our big reasons why we support steel on our products rather than aluminium is because it is SOOO much better at taking abuse under the car as per above. "The choice of steel is a simple one, More rigidity for braces and the weight is honestly not a problem! I have personally had to use a grinder and cut off wheel to remove Gt spec and Tanabe braes. They use a thin aluminium that caves in when hit by a rock, speed bump small child...well you get the point. steel has a much better ability to resist damage while riding under the car!"

#6

We cannot make the bar sit any higher to the vehicle because it will not clear aftermaket and stock S pipes. When we build braces we design them to sit as closr to the vehicle as possible so anytime there is a taller cup its to clear something on the car or for safety. A common thing that happens with other companies is that they will make the braces sit CLOSE to the chassis of the car but the driver will experience a ton of rattling and vibrations from it rubbing up against motor mounts, crossmembers, exhaust systems etc...It really becomes a choice of scraping occasionally or having constant rattles. One of our big reasons why we support steel on our products rather than aluminium is because it is SOOO much better at taking abuse under the car as per above. "The choice of steel is a simple one, More rigidity for braces and the weight is honestly not a problem! I have personally had to use a grinder and cut off wheel to remove Gt spec and Tanabe braes. They use a thin aluminium that caves in when hit by a rock, speed bump small child...well you get the point. steel has a much better ability to resist damage while riding under the car!"

#7

I will be taking my traction bar off this weekend since winter is almost here. All the other braces will be left on. I did spray a couple coats of vht anti corrosion. Lets see thru the harsh winter how these braces handle. I will have feed backs on it too in Spring.

#8

Thread

Thread Starter

Forum

Replies

Last Post

SpaceCaptain

Scion xB 2nd-Gen Suspension & Handling

0

05-11-2015 06:24 PM

carid

Exclusive Sponsored Sales

0

02-12-2015 11:54 AM

JM Auto Racing

Exclusive Sponsored Sales

14

12-19-2014 06:36 PM

carid

Exclusive Sponsored Sales

0

12-16-2014 09:53 AM