a REAL project

#41

Bump -

UPDATE: some plans towards the 3SGTE's turbo setup. i'm going to do a sequential turbo setup specifically because of the AWD and the want of decent power while having nice off the line power at the same time. i'm working on a full chart right now to determine what air flow *lbs/min* is supplied by the 3SGTE while having the available 2.2L stroker thrown into the picture. at the same time, this chart will show what turbos *Garrett Turbos* will be needed and used and will also show how much psi from each turbo will be needed to make whatever power is expected at what ever rpm point.

on the left side of the chart is rpms going up by 500rpm from 0 to 7,000rpm. on the bottom, air flow in pounds per minute *lbs/min* ranging from 0 to 70lbs/min. on the right showing turbo pressure charge per square inch *psi* ranging from 0 to 35psi.

this allows me to find how much air flow the 3SGTE supplies with a 2.2L stroker. after i have finished this part of the chart. i can then skim through all the turbos that Garrett supplies and look at each air flow chart and determine what turbos would be best for the specific application based on pressure ratio vs. air flow. all in all turning the 3SGTE into a 3SGTTE. i'll post up scans of the chart when it's finished with all the math that takes place within the process.

UPDATE: some plans towards the 3SGTE's turbo setup. i'm going to do a sequential turbo setup specifically because of the AWD and the want of decent power while having nice off the line power at the same time. i'm working on a full chart right now to determine what air flow *lbs/min* is supplied by the 3SGTE while having the available 2.2L stroker thrown into the picture. at the same time, this chart will show what turbos *Garrett Turbos* will be needed and used and will also show how much psi from each turbo will be needed to make whatever power is expected at what ever rpm point.

on the left side of the chart is rpms going up by 500rpm from 0 to 7,000rpm. on the bottom, air flow in pounds per minute *lbs/min* ranging from 0 to 70lbs/min. on the right showing turbo pressure charge per square inch *psi* ranging from 0 to 35psi.

this allows me to find how much air flow the 3SGTE supplies with a 2.2L stroker. after i have finished this part of the chart. i can then skim through all the turbos that Garrett supplies and look at each air flow chart and determine what turbos would be best for the specific application based on pressure ratio vs. air flow. all in all turning the 3SGTE into a 3SGTTE. i'll post up scans of the chart when it's finished with all the math that takes place within the process.

#43

wow, i supose i better give a bit up huh?

as for the sequential turbo plan, it's officially going to be a Compound turbo setup, similar to what the diesel guys do, only a much smaller scale. setup will be using a GT2554R turbo as the primary low end turbo and a GT3076R in a 0.82 or 1.06 AR configuration as the secondary pre-compressing turbo. planning on running 20-23 pounds of boost as the medium daily power and the expected top end should be between 40-45psi max out of the compound configuration. this would give a daily 300whp and about a 700whp maximum output.

pistons will be running at 9.0:1, cam rods will be 264/264, head will be fully worked with over sized valves and will be converted from shim over bucket to a 1ZZFE shimless setup and redline will be set at 9,000rpm.

drive-train will consist of a carbonics twin carb disk unsprung clutch assembly and flywheel *comming in at only 22lbs all togethere*. tranny will be re-worked by Fensport with their straight cut gear set and dog engagement with a strain gauge setup for a sequential tranny use for acceleration and possible engine braking.

engine intake manifold will be redone to retain the volume of the inner plenum and the size of the intake charges, but to wrap the charges around to the outer side of the plenum to save room inside of the engine bay while at the same time preventing any need to do any massaging work to the fire wall. this also allows me to setup the throttle in a custom position to optimize and lessen the length of turbo charge piping and increase turbo response.

the new subframes will be fitted so that if there is any need to swap back to the stock block, it will be as simple as removing the 3S engine and bolting the stock 1NZ back in via two different mounting points for the two different engines. this makes it easy to lift the 3S out for it's routine rebuilds *9,000rpm range... 700whp capabilities... you'd be doing the same thing every 50,000miles if not sooner...*.

turbos will be housed in TAIL stainless steel housings so that the use of a added economy boosting water fuel cell to feed hydrogen as a mix fuel. this helps reduce corrosion extremely well over the iron housings that rust. also, in this case that the engine is HIGHLY capable, it has high chance of generating huge amounts of heat which could lead to it overheating. using a hydrogen based mix fuel of gas and hydrogen will help cool the engine from the inside out due to the water vapors going out of the exhaust from the hydrogen carrying some of the heat out from where it starts in the combustion chamber. this also helps with the problem of the need of high octane fuels. the hydrogen will act as the mix fuel's own super octane booster and is expected to be useable with normal 87 octane fuels.

there's some updates for now. i didn't list EVERY LITTLE DETAIL so don't nit pick on things. if anyone is wondering where the funding would be coming from for this project, lets just say... half the work i can do my self and not worry about paying shops, the other half comes from a lovely lawsuit , we put a good amount into CD's and soon will be accessible

, we put a good amount into CD's and soon will be accessible

as for the sequential turbo plan, it's officially going to be a Compound turbo setup, similar to what the diesel guys do, only a much smaller scale. setup will be using a GT2554R turbo as the primary low end turbo and a GT3076R in a 0.82 or 1.06 AR configuration as the secondary pre-compressing turbo. planning on running 20-23 pounds of boost as the medium daily power and the expected top end should be between 40-45psi max out of the compound configuration. this would give a daily 300whp and about a 700whp maximum output.

pistons will be running at 9.0:1, cam rods will be 264/264, head will be fully worked with over sized valves and will be converted from shim over bucket to a 1ZZFE shimless setup and redline will be set at 9,000rpm.

drive-train will consist of a carbonics twin carb disk unsprung clutch assembly and flywheel *comming in at only 22lbs all togethere*. tranny will be re-worked by Fensport with their straight cut gear set and dog engagement with a strain gauge setup for a sequential tranny use for acceleration and possible engine braking.

engine intake manifold will be redone to retain the volume of the inner plenum and the size of the intake charges, but to wrap the charges around to the outer side of the plenum to save room inside of the engine bay while at the same time preventing any need to do any massaging work to the fire wall. this also allows me to setup the throttle in a custom position to optimize and lessen the length of turbo charge piping and increase turbo response.

the new subframes will be fitted so that if there is any need to swap back to the stock block, it will be as simple as removing the 3S engine and bolting the stock 1NZ back in via two different mounting points for the two different engines. this makes it easy to lift the 3S out for it's routine rebuilds *9,000rpm range... 700whp capabilities... you'd be doing the same thing every 50,000miles if not sooner...*.

turbos will be housed in TAIL stainless steel housings so that the use of a added economy boosting water fuel cell to feed hydrogen as a mix fuel. this helps reduce corrosion extremely well over the iron housings that rust. also, in this case that the engine is HIGHLY capable, it has high chance of generating huge amounts of heat which could lead to it overheating. using a hydrogen based mix fuel of gas and hydrogen will help cool the engine from the inside out due to the water vapors going out of the exhaust from the hydrogen carrying some of the heat out from where it starts in the combustion chamber. this also helps with the problem of the need of high octane fuels. the hydrogen will act as the mix fuel's own super octane booster and is expected to be useable with normal 87 octane fuels.

there's some updates for now. i didn't list EVERY LITTLE DETAIL so don't nit pick on things. if anyone is wondering where the funding would be coming from for this project, lets just say... half the work i can do my self and not worry about paying shops, the other half comes from a lovely lawsuit

#44

I commend you on all of your research. That is why 90% of the swaps fail not research into how to do it before hacking the car up.

There is one problem I see in your theory. The dual drivetrain idea. In order to fit the 3GSTE in the "frame rails" you have to notch out a chunk of the dirver's side. This came from the company that built the 3GSTE Yaris. Once this is removed because I think it is the dirver side mount area you can no longer simply bolt the original motor back in. You would have to build an adapter that bolts on to where the 3GSTE is mounted that would provide the mount.

This of course though makes it pointless to swap the two out though.

If someone can put a 365hp WRX engine into a 1965 VW beetle anything can be done.

There is one problem I see in your theory. The dual drivetrain idea. In order to fit the 3GSTE in the "frame rails" you have to notch out a chunk of the dirver's side. This came from the company that built the 3GSTE Yaris. Once this is removed because I think it is the dirver side mount area you can no longer simply bolt the original motor back in. You would have to build an adapter that bolts on to where the 3GSTE is mounted that would provide the mount.

This of course though makes it pointless to swap the two out though.

If someone can put a 365hp WRX engine into a 1965 VW beetle anything can be done.

#47

Originally Posted by ogerdgonz

I commend you on all of your research. That is why 90% of the swaps fail not research into how to do it before hacking the car up.

There is one problem I see in your theory. The dual drivetrain idea. In order to fit the 3GSTE in the "frame rails" you have to notch out a chunk of the dirver's side. This came from the company that built the 3GSTE Yaris. Once this is removed because I think it is the dirver side mount area you can no longer simply bolt the original motor back in. You would have to build an adapter that bolts on to where the 3GSTE is mounted that would provide the mount.

This of course though makes it pointless to swap the two out though.

If someone can put a 365hp WRX engine into a 1965 VW beetle anything can be done.

There is one problem I see in your theory. The dual drivetrain idea. In order to fit the 3GSTE in the "frame rails" you have to notch out a chunk of the dirver's side. This came from the company that built the 3GSTE Yaris. Once this is removed because I think it is the dirver side mount area you can no longer simply bolt the original motor back in. You would have to build an adapter that bolts on to where the 3GSTE is mounted that would provide the mount.

This of course though makes it pointless to swap the two out though.

If someone can put a 365hp WRX engine into a 1965 VW beetle anything can be done.

as for the pics or banned comment, i can't post pictures of something that i don't physically have just yet now can i? research first, build second, that's how this is working. doesn't matter if i have the money to buy a gold nugget or not, i'm not spending my money until i have it all down without error to make it a swift project.

#50

Originally Posted by ogerdgonz

If building a custom tube frame why even bother with the stock motor going back in? Keep it simple and make the new motor work and forget about the paper weight.

#51

In my opinion it would be easier and in the end cheaper to just buy a winter beater. Would rather pull the motor, rebuild it and put it back in. Use the winter beater while rebuilding it.

It is your project so you can do what you choose, but when projects become more complex than needed is when they usually run into problems.

Good luck to you.

It is your project so you can do what you choose, but when projects become more complex than needed is when they usually run into problems.

Good luck to you.

#52

Update

as of now i will have to say i'm going to put 1 to 2 year delay on the project due to schooling. i'm going in for CNC programing and machining for about a year. afterwards i will need time to save up for the initial project.

on the better side of things, i have found an even better candidate for the project...

how many here wish they could roll with a 2JZGTE? i'm sure lots of hands would go up for that... well, sad enough to say, it's not the 2JZ... in fact it's actually the V version of the 2JZ, the 1MZFE. the 1MZFE is lighter then the 3SGTE, it's transmission is lighter then the 3S's E153's AND only requires a small modification to the passenger side of fire wall. this one still requires the factory frame rails to be removed and new custom tube frames to be made. the advantages lay in the bigger litre size of 3litres and a rather nice aftermarket support. it's bore to stroke ratio is a it better with a 87.5mm bore and 83mm stroke compared to the 3S's 86/86, not TOO much more, but just a bit. as of right now, aftermarket support allows a new redline of 8,000+rpm and max boost of around 23lbs based on the valve springs. the 1MZFE is also a non-interference engine and the best version to use right now is the VVTi enabled version due to no new timing gears, timing belt or new cam rods without having to do regrinds. Pauter makes a full set of bullet proof rods, Wisco has pistons and the newer OEM head gasket is a muli-ply metal gasket, perfect for boost.

right now i'm still trying to locate some way of getting ARP studs of all kinds but seems there's another company by the name of AJUSA that makes head bolts for it, but i haven't found anything else. the company that makes the new valve and spring sets is in the middle of making it's next stage for 9,000rpm and 30lbs boost from what i've found and because of the VVTi, on a standalone ecu, you should be able to program it without a problem and see power in those areas as if you changed the cams BECAUSE of the VVTi doing it's job.

as for power, a daily 500hp is more then possible. though for the xB, only a single turbo setup is really possible without having to do a BUTT LOAD more modification to the firewall to fit a twin setup. this swap though would actually cost less then doing a 3SGTE+AWD swap. OH! and the 1MZFE is still capable of AWD, not with the celica's awd though. gotta use the Rav4's 5spd manual 4wd instead.

as of now i will have to say i'm going to put 1 to 2 year delay on the project due to schooling. i'm going in for CNC programing and machining for about a year. afterwards i will need time to save up for the initial project.

on the better side of things, i have found an even better candidate for the project...

how many here wish they could roll with a 2JZGTE? i'm sure lots of hands would go up for that... well, sad enough to say, it's not the 2JZ... in fact it's actually the V version of the 2JZ, the 1MZFE. the 1MZFE is lighter then the 3SGTE, it's transmission is lighter then the 3S's E153's AND only requires a small modification to the passenger side of fire wall. this one still requires the factory frame rails to be removed and new custom tube frames to be made. the advantages lay in the bigger litre size of 3litres and a rather nice aftermarket support. it's bore to stroke ratio is a it better with a 87.5mm bore and 83mm stroke compared to the 3S's 86/86, not TOO much more, but just a bit. as of right now, aftermarket support allows a new redline of 8,000+rpm and max boost of around 23lbs based on the valve springs. the 1MZFE is also a non-interference engine and the best version to use right now is the VVTi enabled version due to no new timing gears, timing belt or new cam rods without having to do regrinds. Pauter makes a full set of bullet proof rods, Wisco has pistons and the newer OEM head gasket is a muli-ply metal gasket, perfect for boost.

right now i'm still trying to locate some way of getting ARP studs of all kinds but seems there's another company by the name of AJUSA that makes head bolts for it, but i haven't found anything else. the company that makes the new valve and spring sets is in the middle of making it's next stage for 9,000rpm and 30lbs boost from what i've found and because of the VVTi, on a standalone ecu, you should be able to program it without a problem and see power in those areas as if you changed the cams BECAUSE of the VVTi doing it's job.

as for power, a daily 500hp is more then possible. though for the xB, only a single turbo setup is really possible without having to do a BUTT LOAD more modification to the firewall to fit a twin setup. this swap though would actually cost less then doing a 3SGTE+AWD swap. OH! and the 1MZFE is still capable of AWD, not with the celica's awd though. gotta use the Rav4's 5spd manual 4wd instead.

#54

Some new research updates!

another all wheel drive option(s) have come up.

1. the older but rare 4WD corolla wagon, though i haven't been able to find much on gear ratios or what exactly the Transmission's ID really is. luckily my father has one of these laying on one of his properties just sitting there with bushings growing over it with fried wiring. it has a Carb'd 4age on it i believe... can't quite remember but i know the engine that's in there is also considered an E and C series transmission based engine. i suspect, because it is a 4WD tranny with high and low on it, it's one of the RXXXF family transmissions seeing as it's only the RXXXF trannys that are 2wd to 4wd changeable with toyota that are small engine / vehicle chassis based.

2. just as option one mentions, i suspect the RXXXF series transmissions to be a capable candidate. it just so happens that the RXXXF series is used on a number of engines that shares bolt patterns to those of E and C series engines. NOW... now comes the hit, the R150F and R151F 5speed 4wd rear wheel drive based transmissions... commonly found on offroad rock climbing toyota 4runners, tacomas and hiluxs.

as earlier stated, the 1MZFE 3.0L V6 engine will fit with little modding difficulty and normally mats to the E350 and E351 trannys. here's the thing, E trannys share the same bolt points for bellhousings from what i've been able to find. the difference is vehicles using E trannys normally have them for a reason, because the vehicle is heavier and the torque stress vs. vehicle weight then becomes too much for the smaller more economy based C transmissions. because of this, the possibility that the RXXXF series transmissions will fit the 1MZFE is VERY possible. also, since there may be a worry about gear strength, the RXXXF trannys have been matted to the infamous 7MGTE which by all means is more then capable of being MUCH more powerful the 1MZFE.

now comes the matter of the two transfer casing styles between the suspected corolla 4WD and the R151F *better option* based transfer cases found on the toyota pickup models. they are huge on the pickup models... really huge and could cause a problem for the front end of the xB after ANY engine is mounted because the transfer cases on the pickups had loads of room with the suspension. so far, this is the only thing i've seen to be in the way. again, i have to have a look at this 4WD corolla and see if it uses the same transfer case setup both front and back.

as it sits though... the idea has stayed the same, with some changes here and there.

no more front wheel drive based drive tran, no more FWD or 4WD. this option may make it RWD or 4WD... even better

as for gear ratios, seems all 5 gears of both the RXXXF series trannys in question are very similar to that of the xB's original C50. only thing i haven't been able to find is what the final drive is for either of the RXXXF trannys. so i haven't been able to find out if the top speed will be any faster or slower then the original 133mph gear limited. so far from what i've found, seems the final is anywhere between 4.30 and 4.56 with a slight possibility of 4.10 being the better. again, first gear is a useless gear again with the R151F due to it being better suited for rock climbing and it's original use as being a buffer gear for the diesel pickup for better off the line acceleration. so it could be anywhere between a rough 120-145mph top speed. i wont know until i've done a bit more research.

another all wheel drive option(s) have come up.

1. the older but rare 4WD corolla wagon, though i haven't been able to find much on gear ratios or what exactly the Transmission's ID really is. luckily my father has one of these laying on one of his properties just sitting there with bushings growing over it with fried wiring. it has a Carb'd 4age on it i believe... can't quite remember but i know the engine that's in there is also considered an E and C series transmission based engine. i suspect, because it is a 4WD tranny with high and low on it, it's one of the RXXXF family transmissions seeing as it's only the RXXXF trannys that are 2wd to 4wd changeable with toyota that are small engine / vehicle chassis based.

2. just as option one mentions, i suspect the RXXXF series transmissions to be a capable candidate. it just so happens that the RXXXF series is used on a number of engines that shares bolt patterns to those of E and C series engines. NOW... now comes the hit, the R150F and R151F 5speed 4wd rear wheel drive based transmissions... commonly found on offroad rock climbing toyota 4runners, tacomas and hiluxs.

as earlier stated, the 1MZFE 3.0L V6 engine will fit with little modding difficulty and normally mats to the E350 and E351 trannys. here's the thing, E trannys share the same bolt points for bellhousings from what i've been able to find. the difference is vehicles using E trannys normally have them for a reason, because the vehicle is heavier and the torque stress vs. vehicle weight then becomes too much for the smaller more economy based C transmissions. because of this, the possibility that the RXXXF series transmissions will fit the 1MZFE is VERY possible. also, since there may be a worry about gear strength, the RXXXF trannys have been matted to the infamous 7MGTE which by all means is more then capable of being MUCH more powerful the 1MZFE.

now comes the matter of the two transfer casing styles between the suspected corolla 4WD and the R151F *better option* based transfer cases found on the toyota pickup models. they are huge on the pickup models... really huge and could cause a problem for the front end of the xB after ANY engine is mounted because the transfer cases on the pickups had loads of room with the suspension. so far, this is the only thing i've seen to be in the way. again, i have to have a look at this 4WD corolla and see if it uses the same transfer case setup both front and back.

as it sits though... the idea has stayed the same, with some changes here and there.

no more front wheel drive based drive tran, no more FWD or 4WD. this option may make it RWD or 4WD... even better

as for gear ratios, seems all 5 gears of both the RXXXF series trannys in question are very similar to that of the xB's original C50. only thing i haven't been able to find is what the final drive is for either of the RXXXF trannys. so i haven't been able to find out if the top speed will be any faster or slower then the original 133mph gear limited. so far from what i've found, seems the final is anywhere between 4.30 and 4.56 with a slight possibility of 4.10 being the better. again, first gear is a useless gear again with the R151F due to it being better suited for rock climbing and it's original use as being a buffer gear for the diesel pickup for better off the line acceleration. so it could be anywhere between a rough 120-145mph top speed. i wont know until i've done a bit more research.

#57

Originally Posted by captdownshift

what happened to you're hydrogen hybrid powered concpet and 1.5l turbo project from earlier in the month?

#58

OK!

last update for a little while so i can get more research in...

another suspicious engine that can be used is the 2GR-FE. Aluminum dual VVT-i based and has been around for while now. it's a 3.5L V6 chain driven and since it's a GR series, it's performance based to begin with. it also gets better fuel economy then the 1MZFE. also, it has dual fuel injection, one in port and one direct. roughly 270hp @ 6200-6400rpm, 250lbs trq. at 4000-4200rpm. normally found matted to a E351 as a manual transmission *hope you TC guys are seeing this* which means it'll support the E153F altrac based drivetrain, if the bell housing doesn't fit, make a new one or find one that fits, but as for the tranny it's self, it should fit, not sure though because i haven't had time to find the spline differences. i DO know that the 2GRFE has been used in toyota's offroad dun buggy sports so there has to be some sort of aftermarket support, agian, i haven't had time to do more research.

until next time...

last update for a little while so i can get more research in...

another suspicious engine that can be used is the 2GR-FE. Aluminum dual VVT-i based and has been around for while now. it's a 3.5L V6 chain driven and since it's a GR series, it's performance based to begin with. it also gets better fuel economy then the 1MZFE. also, it has dual fuel injection, one in port and one direct. roughly 270hp @ 6200-6400rpm, 250lbs trq. at 4000-4200rpm. normally found matted to a E351 as a manual transmission *hope you TC guys are seeing this* which means it'll support the E153F altrac based drivetrain, if the bell housing doesn't fit, make a new one or find one that fits, but as for the tranny it's self, it should fit, not sure though because i haven't had time to find the spline differences. i DO know that the 2GRFE has been used in toyota's offroad dun buggy sports so there has to be some sort of aftermarket support, agian, i haven't had time to do more research.

until next time...

#59

new update...

2GR-FE using the E351 is not so true, it's actualy a revised version of the E153, it's just newer.

also, it LOOKS like the E153F AWD trans will mat to the 2GR without issues of clearance, not exactly sure just yet, but by photo comparison, it MAY fit without issue.

so far, in order to use a similar setup, like using the E153 trans on the 2GR. you need a 1MZFE based fly wheel and then just use a 3SGTE Celica/mr2 based clutch and it's good to go.

also, the 2GR has forged rods in it to begin with so it's pretty beefy. pistons could use replacing but don't know if using too much of a lower compression ratio is a good idea, apparently it's a picky block.

there is no real aftermarket support for the 2GR yet, but you can get a set of eagle rods if you order them custom, can't remember what the charge is, something around 200 per rod.

there are no head stud or bolts available but doesn't seem to need them. the ausy toyota offroad buggy runs the 2GR at roughly 810hp without issues and the only thing the engine has is some eagle H-beam rods, forged pistons and a twin turbo setup... oh and the use of a Sach's clutch but meh, they used a meaty custom sequential trans built for that kind of abuse.

to my understanding right now... the setup would go as follows:

-2GR-FE engine

-GT3582R turbo

-1MZ-FE flywheel or aftermarket 1MZ-FE light weight flywheel.

-E153 transmission for FWD and possibly E153F for AWD.

-any clutch assembly for the ST185 celica, ST205 celica and MR2 3SGTE models will work, just use the 1MZ fly wheel on it.

when it comes to all the little essentials, that's something that will have to be marked down as the project is going under way.

as for power, 10-15psi on the GT3582R within the xB's chassis... you wont want anymore power... i promise you.

2GR-FE using the E351 is not so true, it's actualy a revised version of the E153, it's just newer.

also, it LOOKS like the E153F AWD trans will mat to the 2GR without issues of clearance, not exactly sure just yet, but by photo comparison, it MAY fit without issue.

so far, in order to use a similar setup, like using the E153 trans on the 2GR. you need a 1MZFE based fly wheel and then just use a 3SGTE Celica/mr2 based clutch and it's good to go.

also, the 2GR has forged rods in it to begin with so it's pretty beefy. pistons could use replacing but don't know if using too much of a lower compression ratio is a good idea, apparently it's a picky block.

there is no real aftermarket support for the 2GR yet, but you can get a set of eagle rods if you order them custom, can't remember what the charge is, something around 200 per rod.

there are no head stud or bolts available but doesn't seem to need them. the ausy toyota offroad buggy runs the 2GR at roughly 810hp without issues and the only thing the engine has is some eagle H-beam rods, forged pistons and a twin turbo setup... oh and the use of a Sach's clutch but meh, they used a meaty custom sequential trans built for that kind of abuse.

to my understanding right now... the setup would go as follows:

-2GR-FE engine

-GT3582R turbo

-1MZ-FE flywheel or aftermarket 1MZ-FE light weight flywheel.

-E153 transmission for FWD and possibly E153F for AWD.

-any clutch assembly for the ST185 celica, ST205 celica and MR2 3SGTE models will work, just use the 1MZ fly wheel on it.

when it comes to all the little essentials, that's something that will have to be marked down as the project is going under way.

as for power, 10-15psi on the GT3582R within the xB's chassis... you wont want anymore power... i promise you.

#60

part 2 of recent update.

it may be possible, unsure yet but...

due to the differences between the E153 for the FWD ST18X and ST20X series celicas and the E153 for the 2nd gen MR2 Turbo *93+ turbo E153 tranny* with the starter bolt points being on different sides. the Altrac E153F, or atleast the E151F, the starter bolts to the side of the block on what would be the back side of the engine. the E153 from the 93+ turbo MR2 has it's starter mounted to the trans on what would be the front side of the engine thus why the shifter cable linkage has traded spots aswell.

it may be possible to take a 93+ MR2 turbo tranny and mat the E153F transfer case to the 93+ E153 MR2 turbo trans. the bolt pattern *by comparison of images* looks extremely similar and may be able to fit with little modding. there is one bolt point in question, the loner bolt that pokes out at the top side nearest to the engine. this point may be a bit off, but the rest looks perfect.

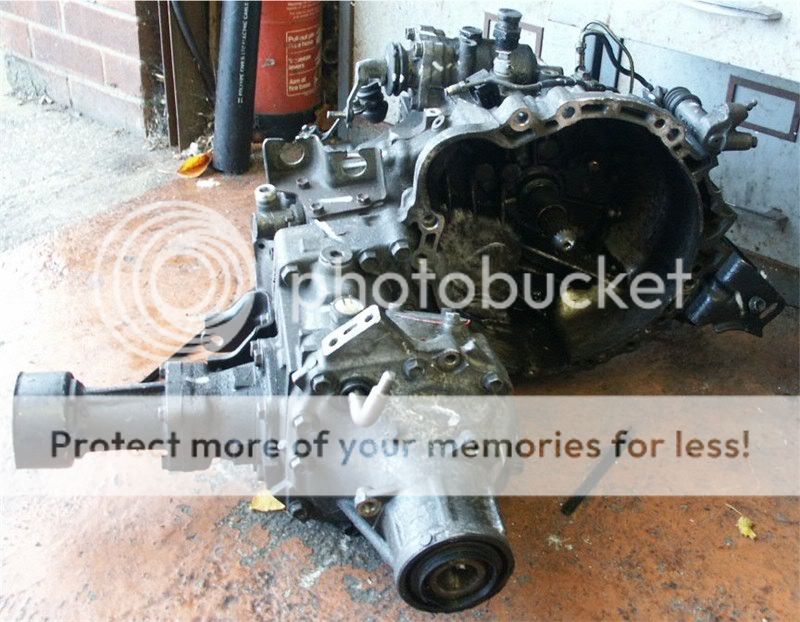

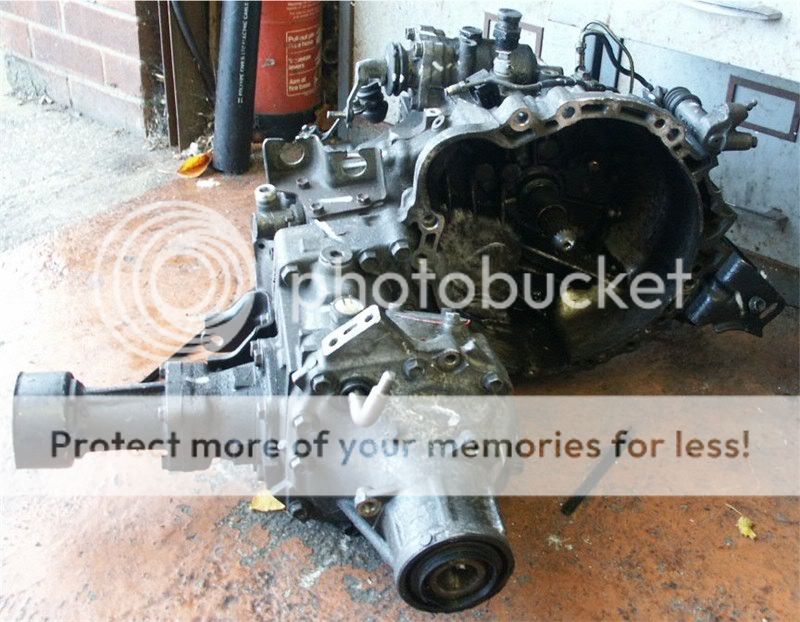

some images below. have a close look at the end of the trans where what WOULD be the passenger *right* drive axle would be going and compare the bolt pattern to that of what can be seen on the E151F trans pictured below the E153 2nd gen turbo trans.

it doesn't matter if it's the transfer case from the E151F or the E153F, they share the same bolt patterns, just stronger internals due to the the ST!85 and ST205 drive trains being nearly the same except for strength.

E153 93+ MR2 turbo trans matted to 2GR-FE engine:

E153 93+ MR2 turbo trans by it's self:

E153 93+ MR2 turbo trans side by side to 2GR-FE:

E153 93+ MR2 turbo trans bolt pattern compared to 2GR-FE bolt pattern, some side drilling required for points 1, 8, 2 and 7. number 6 is smooth and too long and requires a helicoil to be fixed:

ST185 Celica Altrac E151F trans, again, note the transfer case bolt pattern is identical to the E153 93+ MR2 turbo trans:

ST185 celica Altrac E151F trans, another view:

E153 93+ MR2 turbo trans showing new starter bolt point:

the E153F and E151F AWD transfer case should bolt up to the 93+ MR2 E153 turbo trans without much issue at all except for that one bolt. some reiforcement can be done else where to compensate for not having that one bolt there.

it may be possible, unsure yet but...

due to the differences between the E153 for the FWD ST18X and ST20X series celicas and the E153 for the 2nd gen MR2 Turbo *93+ turbo E153 tranny* with the starter bolt points being on different sides. the Altrac E153F, or atleast the E151F, the starter bolts to the side of the block on what would be the back side of the engine. the E153 from the 93+ turbo MR2 has it's starter mounted to the trans on what would be the front side of the engine thus why the shifter cable linkage has traded spots aswell.

it may be possible to take a 93+ MR2 turbo tranny and mat the E153F transfer case to the 93+ E153 MR2 turbo trans. the bolt pattern *by comparison of images* looks extremely similar and may be able to fit with little modding. there is one bolt point in question, the loner bolt that pokes out at the top side nearest to the engine. this point may be a bit off, but the rest looks perfect.

some images below. have a close look at the end of the trans where what WOULD be the passenger *right* drive axle would be going and compare the bolt pattern to that of what can be seen on the E151F trans pictured below the E153 2nd gen turbo trans.

it doesn't matter if it's the transfer case from the E151F or the E153F, they share the same bolt patterns, just stronger internals due to the the ST!85 and ST205 drive trains being nearly the same except for strength.

E153 93+ MR2 turbo trans matted to 2GR-FE engine:

E153 93+ MR2 turbo trans by it's self:

E153 93+ MR2 turbo trans side by side to 2GR-FE:

E153 93+ MR2 turbo trans bolt pattern compared to 2GR-FE bolt pattern, some side drilling required for points 1, 8, 2 and 7. number 6 is smooth and too long and requires a helicoil to be fixed:

ST185 Celica Altrac E151F trans, again, note the transfer case bolt pattern is identical to the E153 93+ MR2 turbo trans:

ST185 celica Altrac E151F trans, another view:

E153 93+ MR2 turbo trans showing new starter bolt point:

the E153F and E151F AWD transfer case should bolt up to the 93+ MR2 E153 turbo trans without much issue at all except for that one bolt. some reiforcement can be done else where to compensate for not having that one bolt there.